Technology & engineering center

As the Dietsmann Group’s Center of Excellence, the Technology & Engineering Center accompanies our clients towards digital transition with Maintenance 4.0.

TECHNOLOGY

As an integrator of innovative solutions, our company supports you in your digital transformation projects. Our services lines (Robotics, Mobility & Digitalization) allow you to increase your productivity.

Let’s Make Maintenance 4.0 a Reality!

ROBOTIZE YOUR INSPECTIONS

Integrator of the ATEX-certified robot: The Inspector, Dietsmann Smart Labs and its partner Taurob offers you excellence in robotics and maintenance 4.0. The Inspector carries out your inspection and maintenance tasks independently in the most extreme environmental and technological conditions (rain, cold, explosive atmosphere).

Benefits:

- Benefit from a powerful robotic application that collects your data 24/7

- Optimize your operating costs

- Improve the availability of your facilities

- Protect and preserve your operators

- Upgrade your HSEQ

Digitalize your processes

CONNECTED TABLETS

Digitalize your inspection and maintenance reports and gain performance! With our solutions, simplify, standardize and digitalize your operating procedures. Our connected tablets can be ATEX certified to meet the constraints of the most complex industrial environments.

Your benefits:

- Digitize your custom procedures

- Carry out your mobility interventions

- Reduce information processing time

- Improve the performance of your operators

- Monitor your equipment

- Ensure the quality of your data

- Automate and standardize reporting

CONNECTED GLASSES

Reduce your costs and carbon footprint while increasing your productivity with connected glasses! Thanks to connected glasses, which can be ATEX-certified, multiply your use cases!

- Remote assistance

- Remote training

- Data visualization

- Hands-free and voice control

Our internal use case: Dietsmann Qualification Center.

ANALYZE YOUR DATA

PREDICTIVE MAINTENANCE

In order to provide fully integrated predictive maintenance, Dietsmann with its field maintenance experience is enriching its services with an advanced analytics solution from Arundo as an advanced data analytics partner.

Predictive maintenance enables to:

- Increase asset availability and production through advanced anomaly detection and failure prediction

- Extend equipment lifetime through optimizing equipment operations

- Reduce maintenance cost through improved planning and execution of maintenance activities

- Improve sustainability performance through improved energy efficiency, reduced CO2 footprint, and emission reduction

- Ensuring site’s and personnel’s safety by maintaining assets’ integrity

Let us empower you with the Predictive Maintenance of tomorrow: as an integrated service.

AUTOMATIC TECHNICAL DATA EXTRACTION

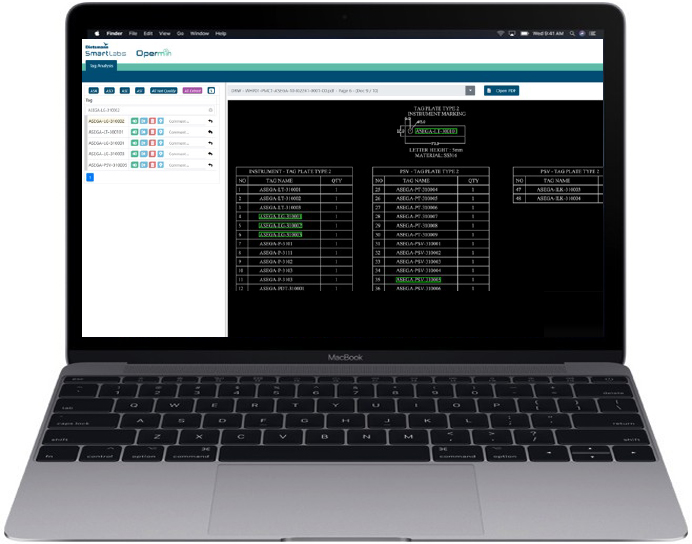

OperMin, developed by Dietsmann Smart Labs, is a platform analyzing technical data of your documentation.

Dietsmann has developed through the Dietsmann Smart Labs this intelligent data analysis and extraction tool detecting relevant information optimized with IA.

OperMin, designed for analyzing large sets of documents, has unique features such as built-in OCR, tables and symbols recognition.

Detect key words and equipment data, extract table and symbols properly in few minutes.

Benefits:

- More reliable Data

- Important time savings

- Automatically Update studies

- More efficient preparation